Mobiles in Metal

Sheet metal is metal formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used in metalworkingand it can be cut and bent into a variety of shapes. Countless everyday objects are fabricated from sheet metal. Thicknesses can vary significantly; extremely thin thicknesses are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate.

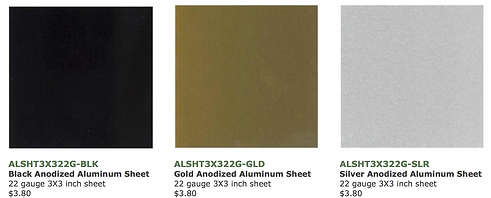

We are using aluminum roof flashing and anodized aluminum sheets.

The thickness of sheet metal is in the USA commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge.

What gauge metal do you think the anodized is?

The flexibility of aluminum makes it resilient to shock of impact, including things like wind, pushing or pulling. For this reason, aluminum is common in aerospace, outdoor structures, and auto manufacturing. Compared to steel, aluminum is about one third as dense and one third as stiff, but we can make a myriad of products using aluminum and can vary the strength easily based on alloys and thickness.

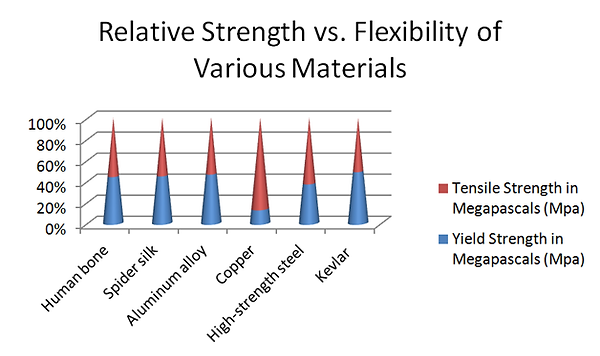

In engineering, the difference between strength and flexibility is referred to as yield point or yield strength. A material flexes elastically when, after the pressure stops, the material returns to its original shape. This is the first thing that happens when stress is applied. A material has deformed plastically if it cannot return to its original shape, and this happens when stress on the material surpasses the yield point.

Another way to measure strength of a material is ultimate tensile strength (TS), which means the amount of pulling or stretching stress something can withstand without breaking. Below is a chart of how far various materials can bend before breaking:

As you can see, the relative strength of aluminum alloys is very high compared to many other metals, and even high-tech fabrics like Kevlar. For this reason, aluminum has a low risk of buckling when used in buildings. It is also lightweight, naturally resists corrosion and conducts heat well, making it great for things like heat sinks.

Content from http://www.futuraind.com/

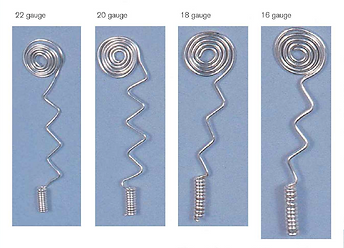

The wire we use also comes in different gauges.

We use galvanized steel wire for jump rings and hoops. The larger the gauge the thinner the metal. So the 22 gauge is much thinner and less strong than the 18 or 16 gauge wire. .

We use welding wire for arms.

The hard, smaller wire is a stainless steel alloy (Alloy means mix of metals):

316L Stainless Steel TIG Welding Alloy, 88000 psi, 0.045 in - Designed for flat and horizontal welding positions - Maximum carbon content is 0.03%Use for high temperature service applications - SS 316L 045 X 36 10#Unit: 1/LBDia.0.0450 in - Tensile Strength88000 psi

The softer, easier to bend more silvery appearance is

ER4043 1/16" Dia X 36" Aluminum TIG Welding Rod in 10 lb box includes aluminum/silicon filler metal for welding heat treatable base metals with improved puddle fluidity and makes a perfect choice for welding 6061.

Anodizing Metal Watch the Engineer Guy explain the Anodizing process of Apple iPhone

Anodizing is an electrochemical process that converts the metal surface into a decorative, durable, corrosion-resistant, anodic oxide finish. Aluminum is ideally suited to anodizing, although other nonferrous metals, such as magnesium and titanium, also can be anodized.

The anodic oxide structure originates from the aluminum substrate and is composed entirely of aluminum oxide. This aluminum oxide is not applied to the surface like paint or plating, but is fully integrated with the underlying aluminum substrate, so it cannot chip or peel. It has a highly ordered, porous structure that allows for secondary processes such as coloring and sealing.

Anodizing is accomplished by immersing the aluminum into an acid electrolyte bath and passing an electric current through the medium. A cathode is mounted to the inside of the anodizing tank; the aluminum acts as an anode, so that oxygen ions are released from the electrolyte to combine with the aluminum atoms at the surface of the part being anodized. Anodizing is, therefore, a matter of highly controlled oxidation—the enhancement of a naturally occurring phenomenon.

Anodized finishes have made aluminum one of the most respected and widely used materials today in the production of thousands of consumer, commercial and industrial products.

Anodized Aluminum:

-

Protects satellites from the harsh environment of space.

-

Used in one of the world's tallest buildings --- the Sears Tower in Chicago, Illinois.

-

Provides attractive, minimum-maintenance, highly durable exteriors, roofs, curtain walls, ceilings, floors, escalators, lobbies and staircases in skyscrapers and commercial buildings throughout the world.

-

Revolutionized the construction of computer hardware, exhibit displays for trade shows, scientific instruments, and a constantly expanding array of home appliances, consumer products, and building materials.

-

Considered environmentally safe, producing few, if any, harmful effects on land, air, or water.

-

Content from http://www.anodizing.org/?page=what_is_anodizing